Recently, Vina-Hydraulic Equipment Joint Stock Company received an order of more than 50 strands of Food Suction and Discharge Hoses from Alfagomma. Order details include:

- 3/4'' food suction and discharge hose for fatty liquids, 10 bar (150 psi) pressure

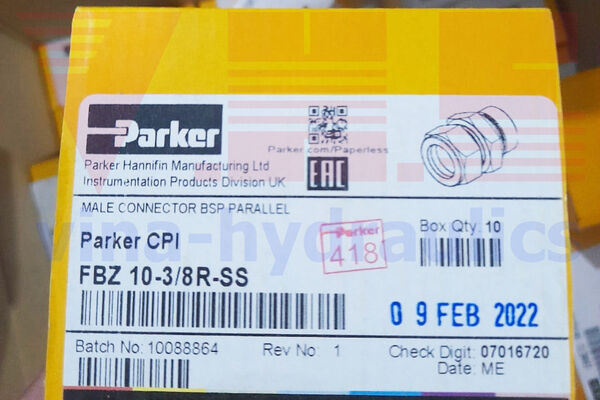

- 3/4" - 3/4" BSPP straight crimp fitting with double-layer stainless steel ferrule

- 3/4" - 3/4" BSPT male thread straight crimp fitting with stainless steel ferrule

About Alfagomma food oil suction hose (Fat food S&D 10 bar (150 psi) FDA - 3-A - D.M. 21/03/73)

The hose meets standards set by the U.S. Food and Drug Administration (FDA), 3-A standards (for hygienic equipment in the dairy and food industries), and Italian standards (D.M. 21/03/73).

- Tube: white NBR.

- Reinforcement: high tensile textile cords with embedded steel helix wire.

- Cover: blue NBR/PVC—abrasion, ozone, and oil resistant.

- Application: liquid and fat food-alcoholic beverages suction and delivery-max 75%.

- Sterilize with 130°C (266°F) steam for 30 minutes or with 5% soda solution.

- Constant operation: -30°C to +100°C (-22°F to +212°F).

Key Features

Materials and Safety: The inner tube is made of white, non-toxic NBR (Nitrile Butadiene Rubber), which is safe for food contact. NBR also has excellent resistance to oils and fats, making it suitable for transferring fatty foods. The outer cover is made of blue NBR/PVC for easy identification, and it is also abrasion-resistant and durable in harsh environmental conditions.

Structure: The inner tube directly contacts the food. The textile cords and a steel wire helix help the hose maintain its shape, preventing it from collapsing under vacuum and allowing it to withstand pressure during discharge. The outer cover protects the reinforcement and inner tube from external damage.

Standards: Compliance with standards like FDA and 3-A is crucial. This ensures the hose is manufactured under strict hygienic procedures and will not alter the taste, smell, or contaminate the food. The 3-A standard is particularly important in the dairy and beverage industries, as it requires smooth, easy-to-clean surfaces to prevent bacterial growth.

Sterilization Capability: The ability to withstand high-temperature steam sterilization (130°C) demonstrates the hose's excellent thermal resistance and its ability to meet the stringent sanitation requirements of the food industry.

In short, this is a specialized industrial hose for transferring liquid food. It is designed for both suction and discharge, ensuring hygiene, high durability, and strong resistance to chemicals and temperature changes during production and cleaning.

VHE (Vina-Hydraulic Equipment Joint Stock Company) currently offers high-precision hydraulic hose crimping services at competitive prices nationwide. With over 12 years of industry experience, VHE is a trusted and reliable partner for hose crimping services to many major businesses in Vietnam. The company also has a team of well-trained technicians who can meet all customer requirements.

For customers who need food suction and discharge hose fabrication, please contact VHE for a consultation!

- Consultation & Support: 0903 967 588 - 0903 067 588

- Email Support: [email protected]

- Office Address: 31 D20 Street, Phuoc Long Ward, Ho Chi Minh City, Vietnam

- HCM Warehouse: Street 10, Song Than Industrial Park, Di An Ward, Ho Chi Minh City, Vietnam

- Hanoi Warehouse: Km28, National Highway 6A, Dong De Industrial Park, Phu Nghia Commune, Hanoi, Vietnam.